- 877.942.5613

- [email protected]

- We Never Close 24/7/365

- 877-942-5613

- [email protected]

Is it Too Cold to Sealcoat my Parking Lot?

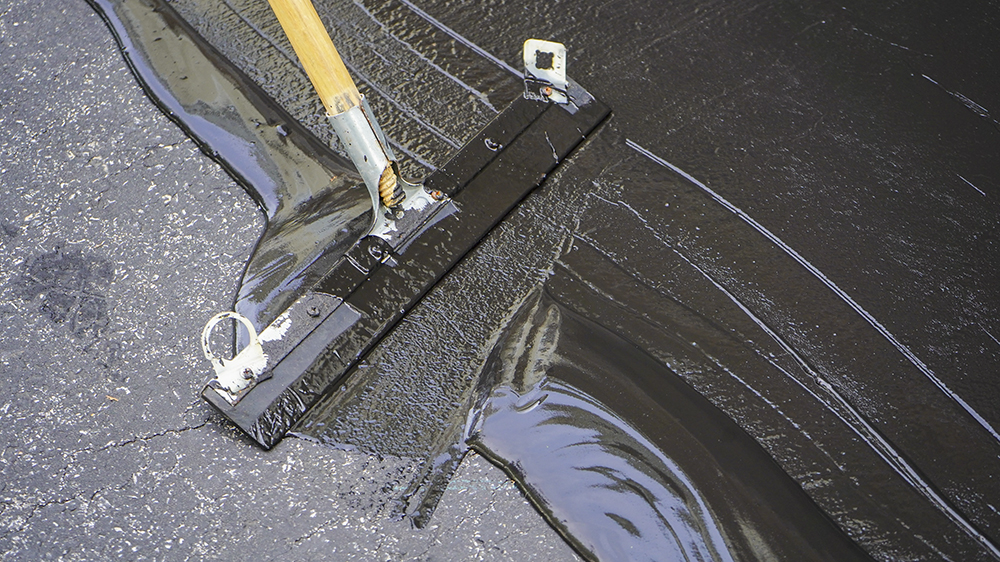

If you own or manage a property in Boston or any other city in the northern half of the US, you may be wondering if you still have time to sealcoat your parking lot before winter arrives. A fresh sealcoating will protect your parking lot from the damaging effects caused by weather and sunlight, as well as keep your parking lot looking fresh.

It is important to hire a professional who understands the sealcoating process, as well as how seasonal weather changes can affect the application and curing of your pavement. Otherwise, you could end up wasting precious time and money.

PaveConnect Can Help You Put a Maintenance Plan Together for Your Parking Lot!

Why Does Cold Affect the Sealcoat Application and Drying Process?

The majority of sealcoatings are water-based coatings, made from either refined tar or asphalt emulsion, which are used to protect and preserve asphalt surfaces. The mix tends to contain roughly 60% – 70% water by volume, having the largest proportion in the sealer mix. Sealcoats cure over time by releasing all stored water into the ambient environment, from top to bottom. As more water escapes from the mix, the more difficult it becomes for the remaining water to escape.

It is imperative that all the water and volatiles be released from the applied sealer mix as even trace amounts of water can freeze and damage the mix should the temperature fall below freezing. If not allowed to cure fully, sealcoats have been known to fail prematurely.

3 Critical Factors for Proper Sealcoat Curing

1. Temperature – Both ambient and pavement temperature must be taken into consideration. High temps favor moisture evaporation, colder temps impede it. The consensus across the paving industry is that sealers are best applied when temperatures are a minimum of 55 degrees and rising. During the first 48 hours of curing, temperatures must remain above 50 degrees to allow ample cure time for the pavement coating.

2. Humidity – Remember, to cure, the sealcoat must be able to release all of its excess moisture. Low humidity facilitates water evaporation whereas high humidity slows the process.

3. Wind – Wind is another factor that aids in the removal of water vapor from the mix.

Each of these factors works in tandem with the other, affecting the curing process of the mix. High temps and low humidity greatly accelerate water evaporation. Conversely, low temps and high humidity provide very poor cure conditions, under which sealer mixes take significantly longer to cure.

Based on the information provided above, it’s understandable why sealcoat takes so much longer to dry under adverse weather conditions. In the fall, many parts of America are beginning to see more of these unfavorable conditions and must take special consideration when considering whether to sealcoat.

If you’re considering sealcoating your parking lot this fall, make sure to hire an experienced professional who will ensure that your new coating is applied correctly and understands what environmental conditions are optimal for curing and which conditions to avoid. The professionals at PaveConnect provide comprehensive paving services across the entire nation. From sealcoating and striping to ADA audits and signage, PaveConnect has experts to handle any project. Call or email us today to schedule your fall parking lot inspection or to discuss your sealcoating options.

Call – 877.942.5613

Email – [email protected]

Looking for a National asphalt paving contractor for your next project?

© 2019 All rights Reserved.